Blog

3 Examples of Mercury Wire’s Custom Cables in Action

How Our Team Partners with Yours to Provide Custom-Cable Solutions

Working as a collective group of experts to help you realize your visions and achieve your goals, we collaborate with you, bringing a wealth of information to the table. The first step is always listening to you and our primary goal is to understand what your needs are so we can build the right custom cable for your application. We’ve written about the six questions you need to consider regarding the materials for your custom-cable project, and you can check that out by clicking here.

Hearing how our approach has been applied with customers might give you a better sense of how well it can work for you to sort through all these considerations at the outset of your next project. Diversity and innovation are strengths of ours for creating integrated cable assembly solutions. We manufacture highly engineered cables and interconnect assemblies for numerous industries and applications—including industrial, medical, marine, and military sectors for applications as vast as video inspection and surveillance, buoyancy control cables, industrial robotics, and environmental monitoring, among them.

We’d like to share with you some real-life examples of successful collaborations with customers. Perhaps it will enable you to envision how a partnership with Mercury Wire can help you achieve your goals on your next project.

1. Addressing a Cracking Problem

A legacy design contained a foam PE jacket that exhibited environmental stress cracking over time and would even show cracks when still on the packaged reel. Mercury Wire offered to blend the PE material with an elastic additive to address this issue. Since this was for a military application, the customer was reluctant to change the jacket recipe because of all the internal approvals that would be involved when making this kind of change. We recommended running samples of the new recipe for the customer to test, which allowed the customer to receive approval for the new design. The new design has shown no cracking to this day, and we were recently contacted again for an updated quote for a possible repeat order—a true sign of customer satisfaction!

2. Staying Afloat with TPU Foam Challenges

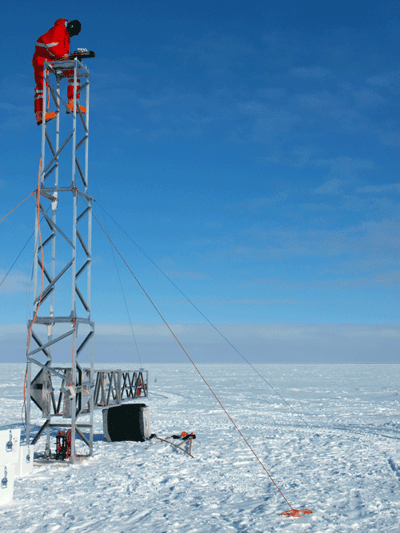

While Mercury Wire’s experience with TPU foam was limited, we didn’t shy away when a customer came to us requiring the wide use of a robust, rugged TPU foam to meet certain buoyancy requirements. In addition to these requirements, there were also continuous length specifications to meet as well. Some challenges we faced involved blisters on the jacket surface and meeting specific gravity requirements for buoyancy. Through the amazing partnership with this customer, we were able to manufacture a product that addressed these issues.

3. Collaborating to Beat the Competitor

This example involves a design that contained several fragile coaxes. The customer approached us to come up with a design concept that would add a star filler to the “nest” of fragile coaxes. After weekly collaborations with the customer, we were able to offer several design ideas that were produced for testing with additional design tweaks made throughout the process. After positive feedback from the customer’s end user, we’ve progressed to the testing phase with them. The current design seems promising, and we’re excited to win this contract with our customer!

Why Choose Mercury Wire?

Our unique partnership approach with customers allows you direct, collaborative access to our dynamic team of experts. Our process allows us to continuously identify, adapt, and implement improvements quickly. Our systems and our team’s flexibility ensure customized high-value development programs. Whether you have a cable design in mind, or you want to come to our factory floor to build a prototype, Mercury Wire can design the best product to meet your precise requirements.

The delivery of custom-designed, highly engineered cables and interconnect assemblies starts with you. We thoroughly research the problem you’re trying to solve—going beyond a list of product specifications to analyze and fully understand your application and business goals. Together, we create a vision for a comprehensive solution that suits your needs and exceeds your expectations.

Mercury Wire manages every phase of your project, from initial development through prototyping and production of custom cables and ready-to-install assemblies. It’s just another way of giving you the highest value and best quality. Contact us today to team up with Mercury Wire!